Converting Food and Beverages to Natural Colors

As a global color and flavor company, Sensient has a unique responsibility to monitor and observe shifts in the use of color by the food and beverage industry. Today, consumer demand for natural ingredients and clean labels continues to rise across all regions of the globe.

While this use of natural colors in new product launches has been pretty consistent over the last several years, many of the most well-known legacy products continue to make use of synthetic colors. This makes sense, as their loyal consumers are very happy with current formulations.

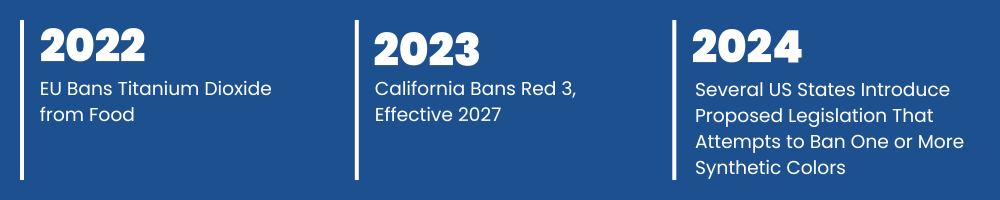

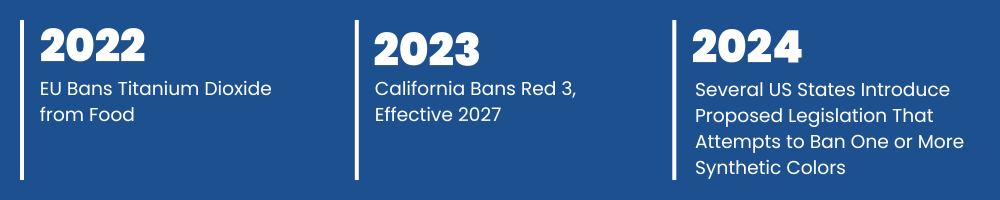

However, recently both NGOs and some regulatory bodies are attempting to expedite the transition to natural colors.

While bans from individual States in the U.S. theoretically apply only to the local jurisdiction, the reality is that food retailing is an industry with national retailers and distribution networks.

In a practical sense, it is impossible for brands and retailers to ensure that products destined for one State would not end up on the shelf of a State where a ban is in place. Hence, the State initiatives end up being de facto national bans.

A similar challenge is faced by brands in regions like Europe, where natural colors are already the norm. The first massive conversion wave from synthetic to natural color usage formed in 2008: the European Commission published specific labelling requirements for six synthetic azo dye colors that almost eliminated their usage in food and beverage products.

Currently, the next phase of conversion is from natural color additives with “e numbers” to “coloring foods” that have more consumer accepted labeling requirements.

Four Key Factors Need To Be Considered to Undertake Conversion Process

Usage Rate Impacts

Work with a color expert to find the best replacements for your current color lineup and formulate with usage rate changes in mind.

Because colors from natural sources are less highly concentrated than synthetic colors, brands should expect to see a volume increase in the color needed to achieve the same shades. Manufacturers can expect a volume increase of 4 to 12 times more material compared to synthetic color volumes when switching to natural solutions.

The increase is dependent on both the shade target and the application or product. More highly concentrated natural colors or coloring foods can help to mitigate the increased usage rate, but higher strength colors will still use more botanical material unless the increased strength is achieved by developing higher pigment material.

Preparing your Facility

Consider investments in refrigeration and storage capacity to handle increased inventory.

While synthetic colors have minimal storage requirements, many natural colors and coloring foods require refrigeration and have a shorter shelf life than their synthetic counterparts. Manufacturers will need to prepare for expanded color product storage and potential refrigeration. The other alternative is to use natural powders, but these generally cost more than liquids.

Securing the Supply Chain

Ask your color supplier about their supply chain security and ability to scale up volume as needed.

Unlike synthetic colors, developing a robust and redundant supply chain security for colors from natural sources is both critical and complex. Since colors from natural botanicals are typically derived from orphan crops, increasing supply to meet growing demand needs to be carefully planned. It is also true that some key botanicals are often grown in only one or two countries. Sensient has invested in vertical integration across many of the most important color botanicals and can scale volume more easily, while also ensuring multi-hemisphere redundancy to reduce climate related risks. However, the scale up process typically will take several years to accomplish. The steps required include seed production, multi-hemisphere planting, primary extraction expansion, and processing expansion (if necessary).

Preparing a Color Partnership

Rather than selecting a preferred formula first and then addressing supply chain, consider addressing technical and supply chain questions concurrently. Develop a timeline that meets your needs with your color partner.

Agronomy and agriculture take time to expand: Even the most prepared color manufacturer may need up to three years to produce large quantities of botanically sourced colors based on growing cycles. Additionally, if every brand on the market is forced to make a swap at the same time, there will be a bottleneck in the supply chain as demand outpaces supply. Forecasting color needs and securing contracts with your color supplier can ensure availability for your products on the timeline you need.

We are ready to help you make this transition smoothly

We anticipate the coming market shift and are readying our supply chain, our manufacturing facilities, and our teams to handle the influx of natural color and coloring foods needs. We encourage our customers to ask your color supplier(s) about their preparation for a color conversion project and the potential for a major market shift forced by consumer demand or regulatory requirements. Are you ready to convert? Learn more by connecting with our team.